All necessary tooling and fixtures are designed and fabricated in-house, affording us complete control over the quality of parts we produce. Our micro-precision deep hole drilling is widely utilized by customers in the firearm industry, but especially when combined with one of our other machining services. This process has widespread applications in a broad range of industries including the medical and aerospace sectors.

Depending on the material and hole size, feed rates up to 40 inches per minute are possible, and drilling can be performed on multiple spindles, expediting total processing time. Tool breakage monitoring systems track the cutting tool in real time to prevent scrap material, which is especially important when drilling high-cost alloys.

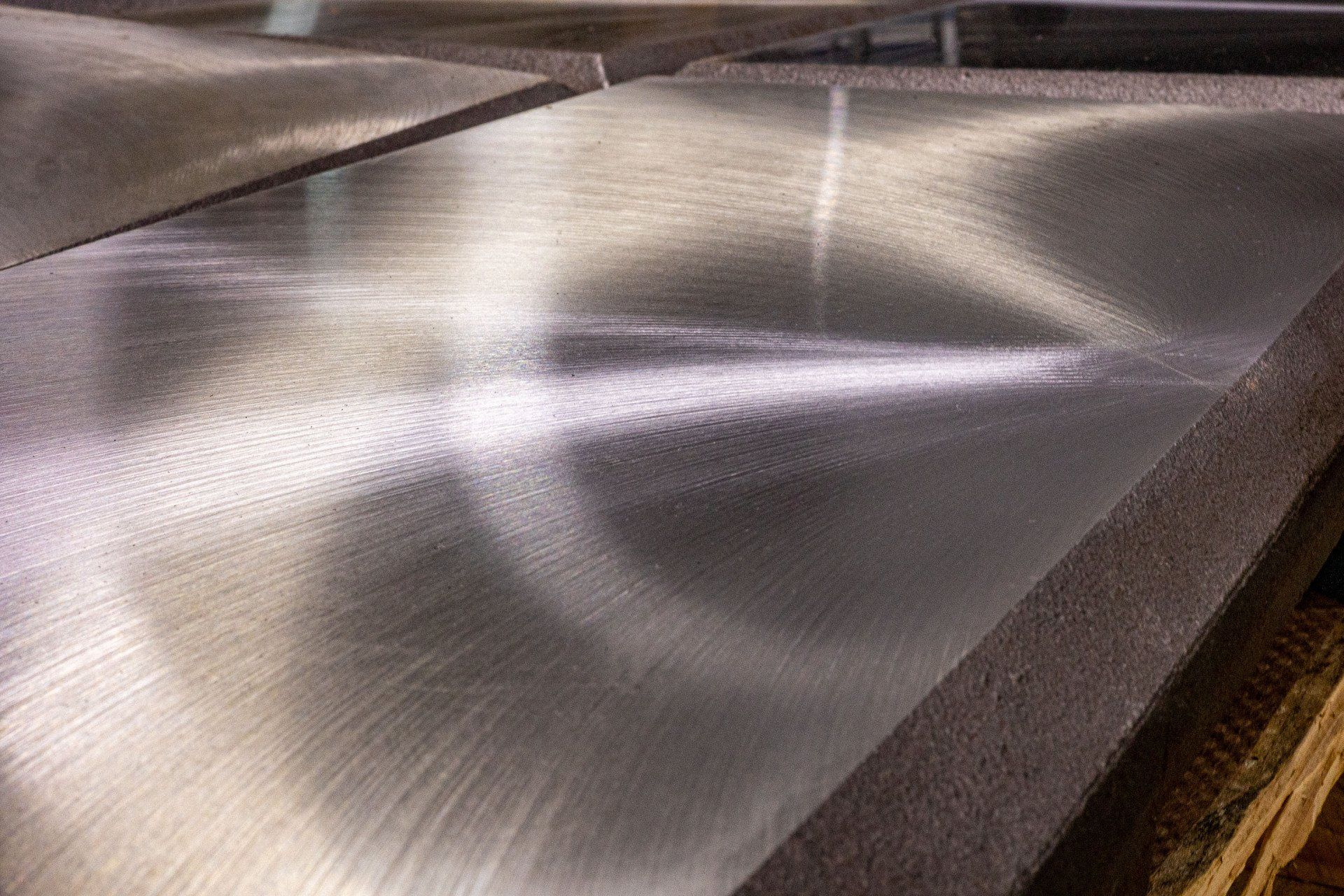

Our engineering and design abilities range from building parts according to provided technical prints all the way to complete design support and solid modeling. Our quality is backed by an extensive history in the machining industry and our ISO 9001:2008 certification. We also provide numerous secondary services such as grinding, plating, and polishing for customers who are seeking a single-source manufacturing solution.