Mill Department

Horizontal & Vertical Milling

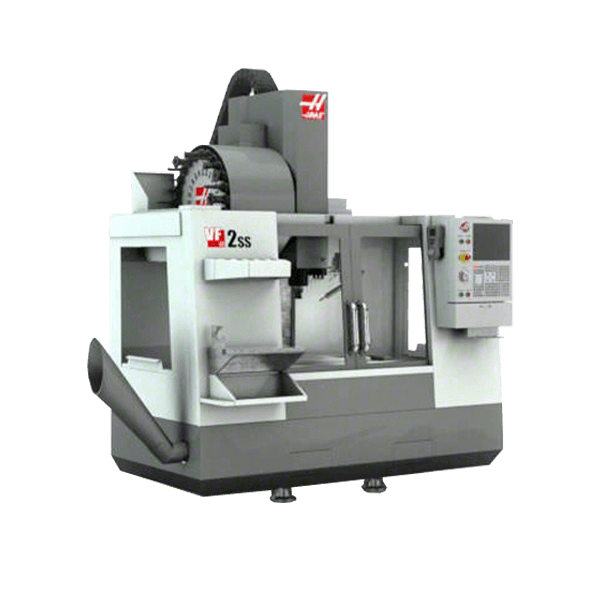

We provide custom CNC machining using vertical milling centers. Vertical milling centers are ideal for machining parts that require extensive material removal as the configuration of the parts facilitates rapid chip removal. Using vertical machining centers, we are capable of facing and creating pockets in complex parts very quickly. Our vertical milling centers have 5-axis machining capabilities, which means most parts can be produced in a single cycle.

CNC milling centers can accommodate parts up to 40” in length, 20” in width and 25” in height. With multiple pieces of equipment at our disposal, we can optimize the manufacturing process to keep lead times and costs as low as possible. All while still providing premium quality, precision machined components in a wide array of materials, sizes, and volumes. We work with standard materials such as steel, stainless steel, and engineering plastics, as well as exotic metals, ceramics, and composites.

For customers seeking a single-source manufacturing solution, we can facilitate any secondary process, such as grinding, plating, and assembly, as needed. In addition to machining production parts, we can provide prototypes and repair existing equipment and machinery components for any industry. All lead times are quoted on a job by job basis, depending on the scope of the project. Expedited service is available to accommodate rush orders in emergency situations. For additional information about our extensive array of custom CNC machining capabilities contact us directly.

Vertical Machining Centers

Our capabilities with the Vertical Milling Centers is very extensive. Our on staff Engineer Runs the time study and machine time through our Cam Works Software to initiate our processes and add to our routing of the job.

Contact

Superior Machine & Tool

6911 Trafalgar St.

Fort Wayne, IN 46803

Superior Machine & Tool

6911 Trafalgar St.

Fort Wayne, IN 46803

All Rights Reserved | Superior Machine & Tool Co.