Swiss Department

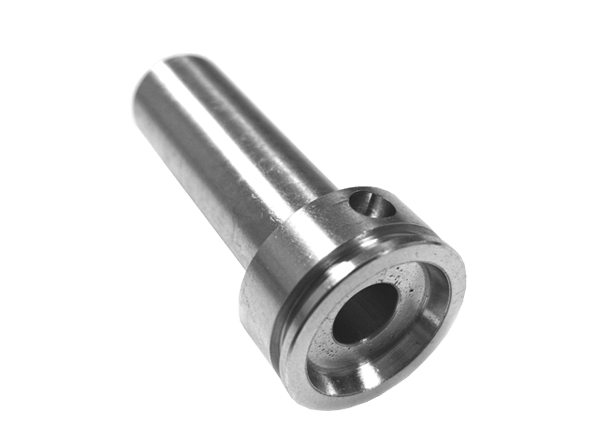

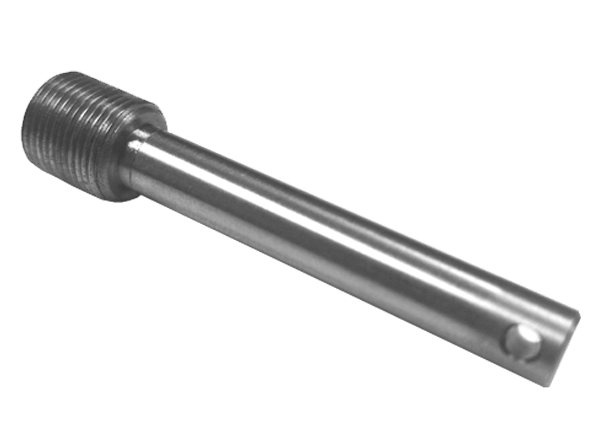

Superior Machine has several Swiss machines, ranging in max bar capacity of 1-1/4″. These machines are excellent for turning high precision parts for medical and aerospace purposes. We also turn barrels for the firearm industry and have high speed drilling attachments for smaller diameter holes.

Our Swiss Machining capabilities at Superior Machine & Tool are utilized to provide precision components for customers in industries such as medical, aerospace, firearms, and many more. We have a total of seven Swiss machining centers capable of machining components made from bar stock up to 1.25” in diameter. Swiss machining can be performed with a wide range of materials, including alloy steel, titanium, aluminum, and brass, as well as nonmetals such engineering plastics including nylon and PTFE compounds.

While we have a wealth of conventional CNC machining capabilities, Swiss machining offers an advantage for applications in which a part has a small diameter to length ratio. For parts that are especially long for their diameter, the stress of the cutting tool can cause excess deflection, making it difficult to hold tight dimensions. In Swiss machining, this issue is overcome by supporting the material with a guide bushing that is located very near the cutting tool.

Originally developed to manufacture the small precision components used in Swiss watches, Swiss machining remains the premiere method for machining medium to high volume pins, fasteners, firearm barrels, and machinery components. In addition to standard Swiss machining tooling, we have high-speed attachments that can be used to drill very small diameter holes, adding to the applications in which Swiss machining is a possibility.

In addition to Swiss machining, we offer CNC turning and milling, deep hole drilling, and precision grinding. These processes can be used to produce larger part sizes or lower part volumes that are not economically feasible for Swiss machining. By offering multiple machining options, our team can provide customers with the most efficient solution for their specific application.

Components can either be machined from customer provided drawings or reverse engineered from physical parts when a print is not available. We have complete CAD drafting abilities, including 3D modeling when needed. Our quality is backed by our ISO 9001:2008 certification and a machining history that dates back to 1936. All lead times are quoted on a job by job basis, with rush services available as needed to accommodate emergency situations. For additional information about our Swiss machining capabilities, contact us directly.

Contact

Superior Machine & Tool

6911 Trafalgar St.

Fort Wayne, IN 46803

Superior Machine & Tool

6911 Trafalgar St.

Fort Wayne, IN 46803

All Rights Reserved | Superior Machine & Tool Co.